Oil mists in the heat treatment process of brake pads

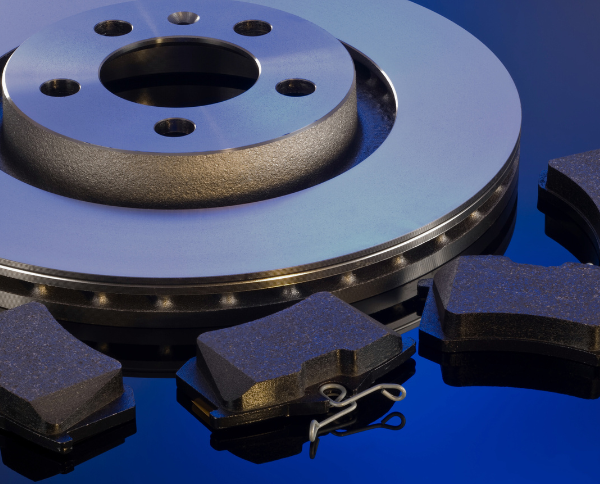

This case study is about the collaboration with an Italian company specializing in the production of brake pads. The client has 30 ovens, each equipped with a chimney without a filtering system. During the heat treatment process, oil residues on the brakes evaporate, causing the emission of oil mists and unpleasant odors. The customer's goal is to reduce these emissions and improve overall environmental management.

Problems

- Unfiltered emissions cause increased VOCs and odors, impacting air quality

- Limited available space

- Flue gas temperature at 90°C: it is necessary to reduce the temperature to 40°C to ensure the safety and efficiency of the system

- 24h operation

Technical features MCOS04

- MCOS04 with integrated No. 2 air- water coils

- F9 filter panels

- Fan with 7.5 kW motor

- Flow rate: 6,000 m3/h

- No.1 air regulation valve

- Electrical panel with pressure transducer

HFiltration designed and installed a special MCOS filter with two air-water coils in parallel to effectively reduce the temperature of smoke generated by furnaces. This filter, strategically placed above the furnace is combined with high- quality filter panels to capture oil mists. In addition, the system includes a powerful fan and electrical panel to monitor and maintain constant air flow, ensuring smooth operation and optimal emission management in a cleaner and healthier working environment.

- Reduced emissions

- Improved airflow management

- Quick installation

- Constant HF monitoring

- Limited costs

- Cleaner and healthier working environment