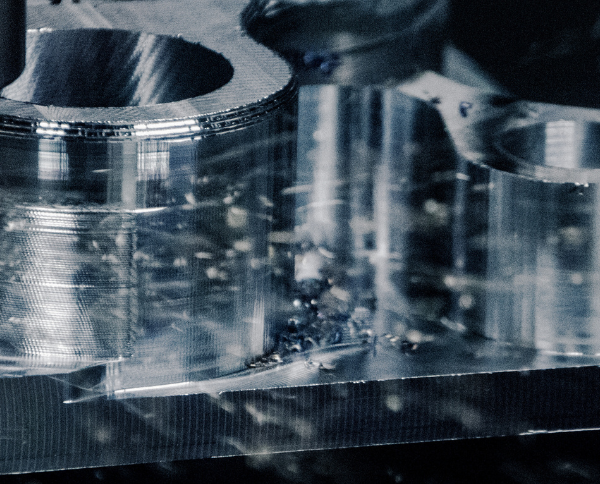

Treatment of oil mists in the metal processing industry

This case study describes the intervention carried out for a Polish company operating in the metalworking industry with CNC machines. The client was managing a single centralized filtration unit that served 8 machine tools, with an electrical panel equipped with an inverter (VFD). However, due to limited space available inside the plant, the filtration unit was installed outdoors, with the integration of a seasonal by-pass system. The client needed to treat the oil mists generated during the machining processes, requiring an efficient technical solution tailored to the specific needs of the production environment.

Problems

- High concentration of oil mists, especially in winter.

- Limited space for system installation.

- Work environment compromised by dust and mists, posing health risks.

Technical features MIST COMPACT

- MC12TV with air flow rate of 10,000 m3/h

- Class H13 cartridges

- An electrical control unit with inverter

- Pressure sensors

- An HFSIL-02 silencer

HF proposed the Mist Compact filter, chosen for its effectiveness in treating oil mists, improving air quality, and reducing health risks. The outdoor installation optimized space, while the by-pass system ensured seasonal flexibility.

- Reduction in energy costs through targeted use of machines.

- Lower consumption and reduced pollution thanks to the seasonal by-pass system.

- Cleaner and healthier production environment.

- Increased workplace safety with lower maintenance costs and simplified management.