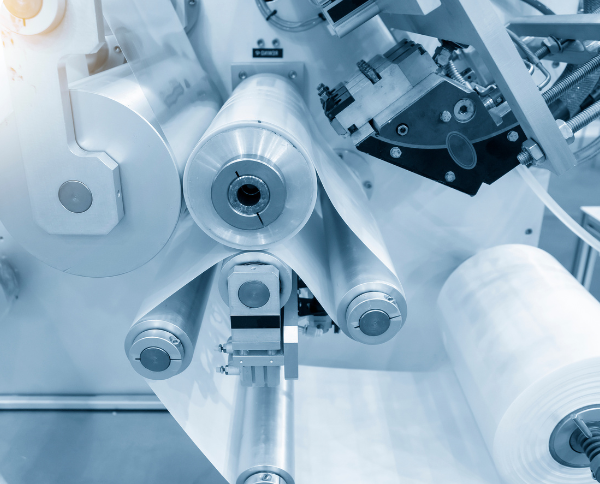

Dust treatment in the production of extrusion machines

In this case study, we discuss an Italian company located in northern Italy that specializes in the production of extrusion machinery. The company was facing the problem of dust and fume removal in the material testing area for machinery. They were looking for an effective and fast solution with a hydrodynamic filter, a technology not widely available in Italy.

Problems

- Need to remove dust and fumes in the material testing area for machinery.

- Need to find an efficient and quick solution.

Technical features IDRODUST 108 V

- Flow rate: Idrodust ID108V air flow 7.000 mc/h

- N ° 5 of suction points: (2 + 3 suction arms)

- N° 1 of motorfans: 7,5 kW

- Pipe Line complete of suctions points Mechanical Assembly

- HFmonitoring 4.0

- Power Electric Board inverter

HFiltration responded promptly by offering the Idrodust Compact filter, an optimal solution due to its quick delivery and installation. The machine, developed on two floors, was successfully installed, ensuring a clean and safe working environment for the customer. This solution allowed the company to continue its testing without interruption, while improving air quality in the work area.

- Clean machinery and longer life of some patents

- Saves money on cleaning

- Emissions reduced to 10 mg