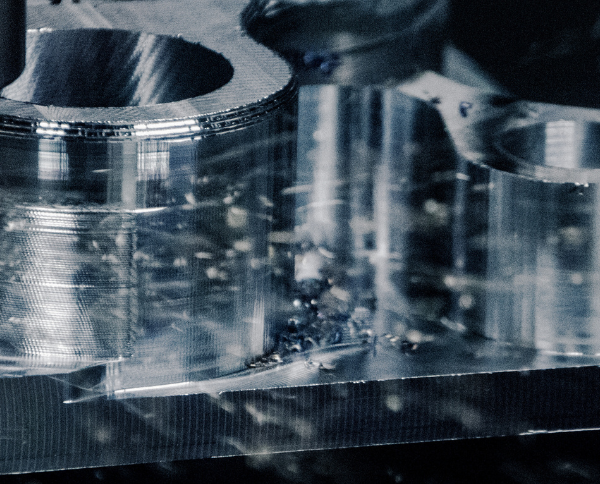

Centrifugal filter for oil mist extraction

CLEANMIST PRO™

The new CLEANMIST PRO range includes a series of centrifugal filters for oil mist. Designed, engineered, and patented, the new CLEANMIST PRO range offers high performance, superior efficiency, and ease of maintenance.

Polluted air is drawn in through the inlet via the centrifugal motion of a bladed impeller equipped with controlled-density bulpren panels. As the air passes through these panels, the particles undergo a coalescence effect, turning into droplets that are then drained outside through a dedicated discharge pipe.

A subsequent filtration stage, utilizing the physical principle of coalescence combined with an FFA fiberglass filtering medium, ensures an efficiency of 99.99%, a figure supported by tests conducted at production sites by accredited laboratories.

APPLICATIONS

- Sharpening

- Boring

- Aluminum and zinc

- Other applications

- Hazardous environments

- Agricultural operations

- Broaching

- VOC

- Drying

- Threading and tapping

- Bag filter

- Square filter

- Filter

- Drilling

- Milling

- Dry fumes and dust

- Shot blasting

- Laser cutting

- Chemical analysis laboratories

- Food processing

- Electroplating

- Marble processing

- Food oil processing

- CNC machining

- Lathe machining

- Various machining processes

- Sanding

- Metal cleaning machines

- Oily mists

- Emulsion atomization

- Neat oil atomization

- Shot peening

- Dust with sparks

- Presence of oil

- Die casting

- Asphalt/bitumen production

- Cosmetics production

- Metal cleaning

- Cleaning

- Grinding and superfinishing

- Metal salting

- Grinding and deburring

- Storage

- Saw cutting

- Cutting

- Mixing and weighing of powdery solid materials

- Steel industry

- Heat treatments

- Painting

- Glassware

- Machining on machine tools

- Chemical processes

- Cement

- Pharmaceutical processing

- Carbon

- Plastics processing

- Welding

- Plasma cutting

- Epoxy coatings

- Grinding

- Wenting silos

- Sandblasting

- Deburring

- Cardiac System

- Respiratory System

- Combustion

- Dentition

- Volcanic Eruptions

- Milling-153

- Metal materials fusion

- Incineration plants

- Paper industry

- Processes with odorous emissions

- Processes with graphite

- Processes with combustible powders

- Woodworking

- Pickling lines

- Metal washing machines-139

- Small metal parts

- Leather

- Eye problems

- Passivation process

- Feed production

- Adhesive tape production

- Abrasive products production

- Superfinishing grinding

- Grinding

- Satin finishing

- Metal satin finishing

- Nervous System

- Waste disposal

- Colis-calamina leveling

- Storage, handling, and pneumatic transport of powdery solid materials

- Storage and handling of powdery solid materials

- Waste storage

- Thermal cutting

- Heat Treatments and Finishing Processes

- Wastewater treatment

- Paints and solvents

- Foundries

- Hot/cold stamping

- Rubber industry

- Industrial frying

- Innovative filtration technology

- High performance

- Reduced noise levels

- Compact and innovative design

- Easy installation

- Low-maintenance and user-friendly operation

- Technical support and after-sales service

- Remote monitoring capability

- Easy-to-read visual LED indicator for optimal operating conditions

Versions

Request the brochure

Fill out now our form below to receive the brochure. Fields marked with an asterisk are mandatory!

Tell us your needs

Fill out our form below and you will be contacted by one of our experts as soon as possible! You will have the opportunity to share all your needs. Fields marked with an asterisk are mandatory!