Oil mist static filter

MIST COMPACT™

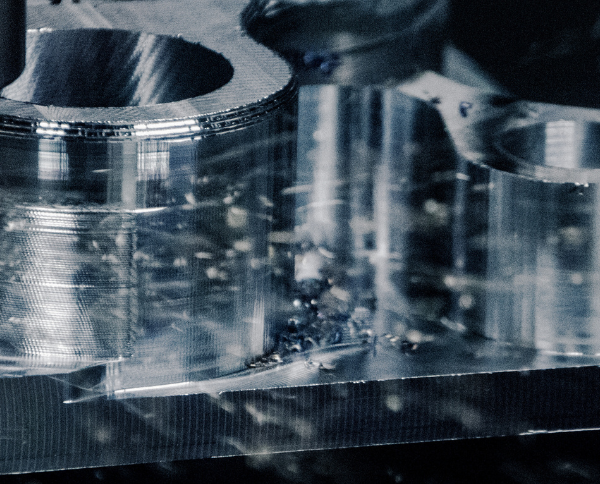

The MIST COMPACT® oil mist filter is designed to build centralised systems. It is a coalescent effect filter for the abatement of emulsified oil mists, composed of folded fibreglass cartridges with H13 efficiency and an external polypropylene membrane.

The MIST COMPACT® structure is equipped with a wide inspection panel to facilitate all assembly and maintenance operations.

The polluted air enters the filter through a plenum that helps slowdown the flow and decay of coarser particles. Wastewater first passes through a metal lattice pre-separator, then through the fibreglass cartridges depositing the contaminant outside them, while clean air is removed from the filter head.

The collected oil particles are expelled through a drain pipe positioned on the back of the filter.

The MIST COMPACT® structure is equipped with a wide inspection panel to facilitate all assembly and maintenance operations.

APPLICATIONS

- Sharpening

- Boring

- Aluminum and zinc

- Other applications

- Hazardous environments

- Agricultural operations

- Broaching

- VOC

- Drying

- Threading and tapping

- Bag filter

- Square filter

- Filter

- Drilling

- Milling

- Dry fumes and dust

- Shot blasting

- Laser cutting

- Chemical analysis laboratories

- Food processing

- Electroplating

- Marble processing

- Food oil processing

- CNC machining

- Lathe machining

- Various machining processes

- Sanding

- Metal cleaning machines

- Oily mists

- Emulsion atomization

- Neat oil atomization

- Shot peening

- Dust with sparks

- Presence of oil

- Die casting

- Asphalt/bitumen production

- Cosmetics production

- Metal cleaning

- Cleaning

- Grinding and superfinishing

- Metal salting

- Grinding and deburring

- Storage

- Saw cutting

- Cutting

- Mixing and weighing of powdery solid materials

- Steel industry

- Heat treatments

- Painting

- Glassware

- Machining on machine tools

- Chemical processes

- Cement

- Pharmaceutical processing

- Carbon

- Plastics processing

- Welding

- Plasma cutting

- Epoxy coatings

- Grinding

- Wenting silos

- Sandblasting

- Deburring

- Cardiac System

- Respiratory System

- Combustion

- Dentition

- Volcanic Eruptions

- Milling-153

- Metal materials fusion

- Incineration plants

- Paper industry

- Processes with odorous emissions

- Processes with graphite

- Processes with combustible powders

- Woodworking

- Pickling lines

- Metal washing machines-139

- Small metal parts

- Leather

- Eye problems

- Passivation process

- Feed production

- Adhesive tape production

- Abrasive products production

- Superfinishing grinding

- Grinding

- Satin finishing

- Metal satin finishing

- Nervous System

- Waste disposal

- Colis-calamina leveling

- Storage, handling, and pneumatic transport of powdery solid materials

- Storage and handling of powdery solid materials

- Waste storage

- Thermal cutting

- Heat Treatments and Finishing Processes

- Wastewater treatment

- Paints and solvents

- Foundries

- Hot/cold stamping

- Rubber industry

- Industrial frying

- Efficiency: Efficiency: Emissions ≤ 5mg/Nm³*

*Other emissions obtainable on request - Improvement of the work environment

- Easy installation

- Customised plant engineering solutions

- Reduced management and maintenance costs

Versions

The V series of Mist Compact® static filters are fitted with centrifugal electric fans (with EU motor with IE3 efficiency) designed to be installed inside the filter to reduce noise and installation space.

To allow installations with customised capacities and heads, Mist Compact® S series static filters can be fitted with a fan installed on the ground.

Request the brochure

Fill out now our form below to receive the brochure. Fields marked with an asterisk are mandatory!

Tell us your needs

Fill out our form below and you will be contacted by one of our experts as soon as possible! You will have the opportunity to share all your needs. Fields marked with an asterisk are mandatory!