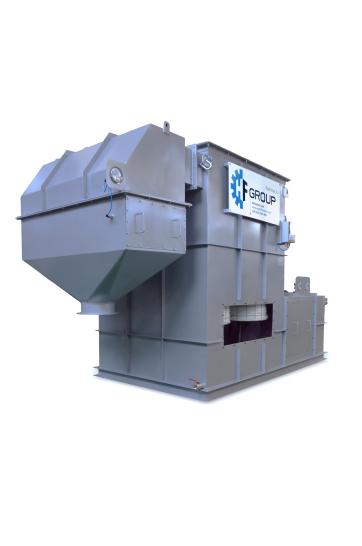

Coalescence filters with fiberglass cartridges

for heavy-duty processes

The coalescence filters with fiberglass cartridges are an advanced solution for the separation and purification of gas streams containing oil mists, submicron liquid particles, contaminated fumes, or industrial aerosols. Their structure consists of cylindrical filtering elements—commonly referred to as candles—made from high-efficiency fibrous materials such as fiberglass, arranged to maximize the filtering surface.

This technology leverages the principle of coalescence, which is the ability to aggregate microdroplets dispersed in a gas stream into larger, more easily separable particles. These droplets are captured by the filter fibers and coalesce into larger drops that can then be drained by gravity into a collector, enabling effective purification even of submicron mists.

Thanks to their high filtration efficiency (up to 99.99% for particles smaller than 1 micron) and robust construction, coalescence filters are particularly suitable for heavy-duty, continuous applications typical of the metallurgical, chemical, bitumen, food processing, and heat treatment industries. They are also used as intermediate stages in multi-stage purification plants, in combination with dry filters, scrubbers, or odor and VOC abatement systems.

This versatility, combined with ease of maintenance and the long service life of the filter cartridges, makes candle filters an extremely reliable solution for ensuring air quality in the most demanding production processes.

Operating Principle

The filters with fiberglass cartridges operate based on the coalescence phenomenon. The contaminated gas stream passes through the filter cartridges: liquid particles (such as oil mist) or solids are trapped within the filter fibers, where they aggregate into larger droplets that are then drained by gravity.

The cartridges are generally composed of multiple layers:

- Prefiltration layer (e.g., cellulose or metal mesh),

- Coalescing section (fiberglass),

- External protective support (e.g., polyester).

Submicron separation is made possible by the Brownian motion of the smallest particles, which are effectively captured even below 1 micron. Typical efficiency ranges from 99% to 99.98% for particles as small as 0.1 microns.

Technical Specifications

- Air/gas flow rate treated: from 750 m³/h up to over 100,000 m³/h.

- Number of cartridges: from 1 to over 99 units, with a diameter of Ø600 mm and a height of 1,200 mm.

- Filter material: fiberglass, multilayer with external polyester support.

- Filtration efficiency:

- 100% for particles ≥ 3 microns,

- 99.98% for particles

- 99.9% for particles ≥ 0.3 microns.

Accessories / Optional Components

- Remote monitoring of operating data via HF monitoring platform.

- Option to install systems for recovery of oil/fluids collected in the hopper.

APPLICATIONS

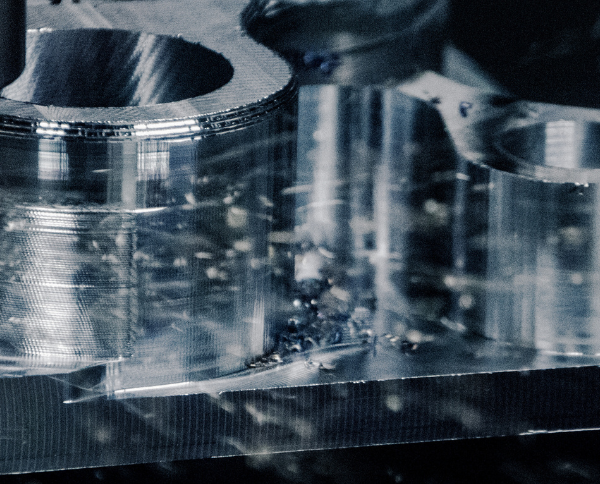

- Sharpening

- Boring

- Aluminum and zinc

- Other applications

- Hazardous environments

- Agricultural operations

- Broaching

- VOC

- Drying

- Threading and tapping

- Bag filter

- Square filter

- Filter

- Drilling

- Milling

- Dry fumes and dust

- Shot blasting

- Laser cutting

- Chemical analysis laboratories

- Food processing

- Electroplating

- Marble processing

- Food oil processing

- CNC machining

- Lathe machining

- Various machining processes

- Sanding

- Metal cleaning machines

- Oily mists

- Emulsion atomization

- Neat oil atomization

- Shot peening

- Dust with sparks

- Presence of oil

- Die casting

- Asphalt/bitumen production

- Cosmetics production

- Metal cleaning

- Cleaning

- Grinding and superfinishing

- Metal salting

- Grinding and deburring

- Storage

- Saw cutting

- Cutting

- Mixing and weighing of powdery solid materials

- Steel industry

- Heat treatments

- Painting

- Glassware

- Machining on machine tools

- Chemical processes

- Cement

- Pharmaceutical processing

- Carbon

- Plastics processing

- Welding

- Plasma cutting

- Epoxy coatings

- Grinding

- Wenting silos

- Sandblasting

- Deburring

- Cardiac System

- Respiratory System

- Combustion

- Dentition

- Volcanic Eruptions

- Milling-153

- Metal materials fusion

- Incineration plants

- Paper industry

- Processes with odorous emissions

- Processes with graphite

- Processes with combustible powders

- Woodworking

- Pickling lines

- Metal washing machines-139

- Small metal parts

- Leather

- Eye problems

- Passivation process

- Feed production

- Adhesive tape production

- Abrasive products production

- Superfinishing grinding

- Grinding

- Satin finishing

- Metal satin finishing

- Nervous System

- Waste disposal

- Colis-calamina leveling

- Storage, handling, and pneumatic transport of powdery solid materials

- Storage and handling of powdery solid materials

- Waste storage

- Thermal cutting

- Heat Treatments and Finishing Processes

- Wastewater treatment

- Paints and solvents

- Foundries

- Hot/cold stamping

- Rubber industry

- Industrial frying

- High efficiency even with submicron particles (up to 99.99%).

- Compact design

- Low maintenance: cartridge service life up to 20,000 hours.

- Durability and strength: stainless steel construction and corrosion-resistant fiberglass filters.

- Reduced pressure drop thanks to aerodynamic configurations.

- CE/ErP regulatory compliance

- Compatibility with remote monitoring systems.

Versions

Request the brochure

Fill out now our form below to receive the brochure. Fields marked with an asterisk are mandatory!

Tell us your needs

Fill out our form below and you will be contacted by one of our experts as soon as possible! You will have the opportunity to share all your needs. Fields marked with an asterisk are mandatory!