Treatment of oil mists in battery production

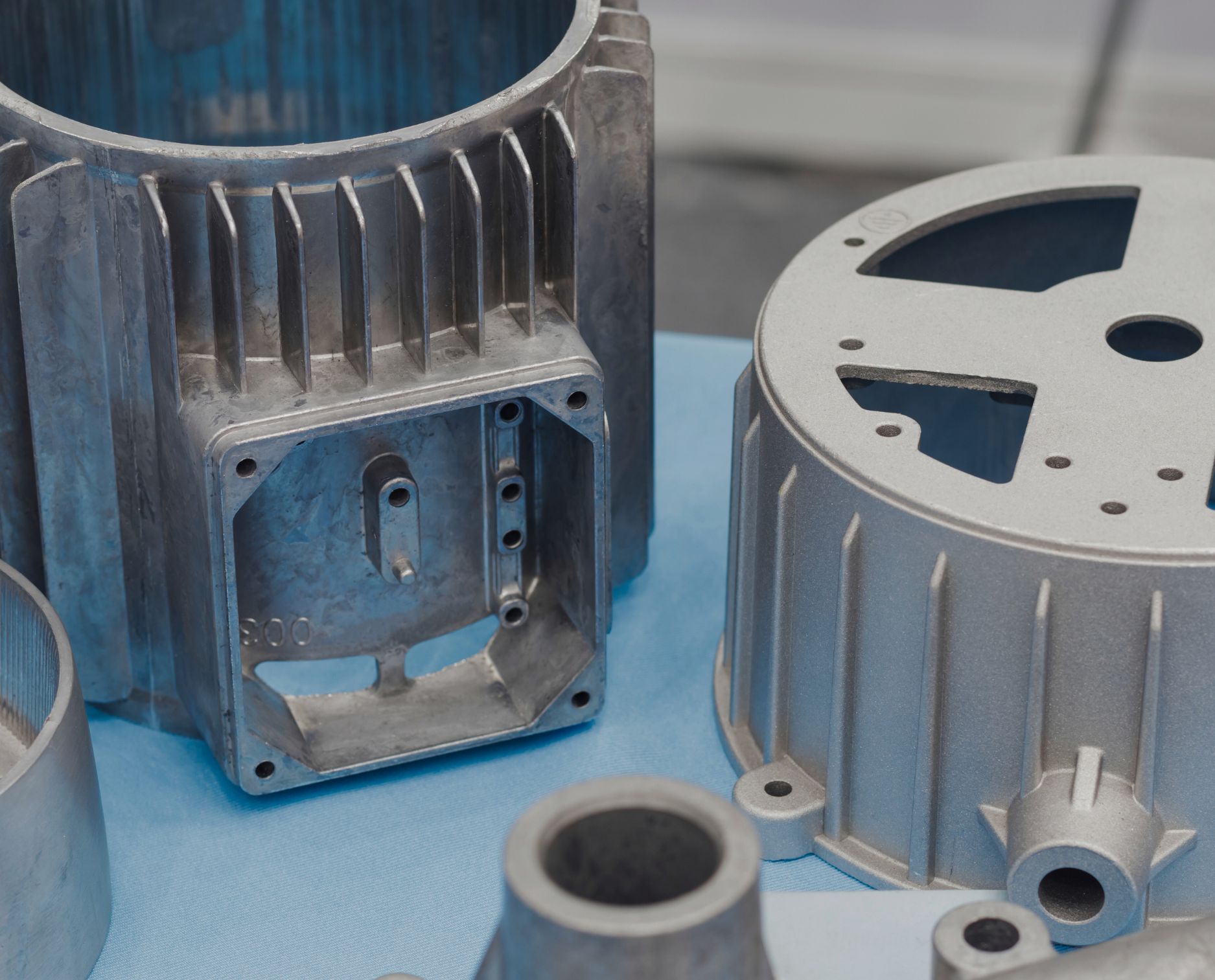

HF Group successfully solved an oil mist problem for a partner active in the battery production sector and specialised in die casting. The customer had been working with us for several years and once again turned to HF Group to find an effective solution to the management of fumes generated during the lubrication process. After a careful analysis of the problem, we found the most suitable solution.

Problems

- The customer has several die-casting lines that generate fumes.

- The problem is caused by burnt oil, used during the lubrication phase, emitting fumes.

- Need to solve the problem without compromising the quality and efficiency of the production process.

Technical features MCOS

- Filter: MCOS08#S, including manifolds

- Flow rate: 15,000 m³/h

- No. 6 suction points

- Efficiency: H13

- No. of fans: 1 PR550 22kW

- Head static pressure: 3,500 Pa

- Outdoor installation

Initially, the customer suggested the installation of a Mist Compact filter. However, after further analysis, we realised that the lubricant was not only liquid, but also generated smoke. We therefore identified as the optimal solution the installation of a MCOS08#S coalescence filter, which can effectively treat both the oil and the smoke generated by the process.

- Fumes are properly extracted from the work area without damaging machines and tools.

- Elimination of smoke dispersion into the atmosphere.

- Improved working conditions, with a cleaner and safer environment.