Explosive dust treatment in the automotive sector

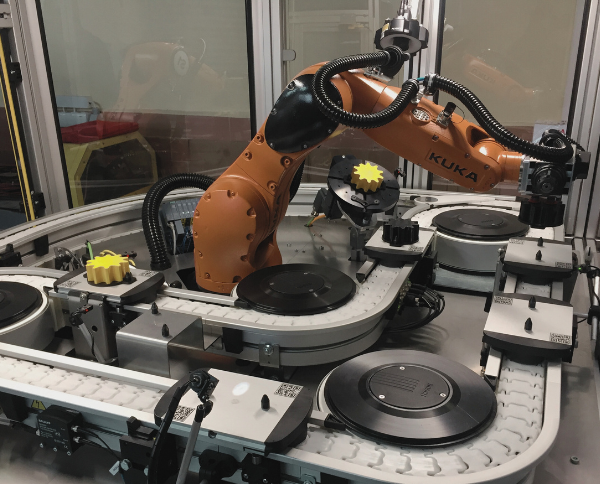

In this case study, we present a solution implemented for a Polish company operating in the automotive sector, specializing in R&D activities and production services for the industry. The customer is involved in the design and manufacturing of tooling, control systems, testing devices, and production support solutions, using high-precision machining centers for complex mechanical processes.

Problems

- Use of a 5-axis machining center for dry machining operations

- Generation of large quantities of dust and microscopic particles

- Machining of different materials (resins, wood, tooling boards, aluminum alloys)

- Presence of potentially explosive dust

- Need to ensure high safety standards

- Requirement to maintain stable thermal conditions within the production cell

Technical Features PC ATEX

- No. 1 Pulsatron Compact ATEX

- Explosion safety device (ATEX flap)

- Dedicated extraction for a 5-axis machining center

- Air recirculation system with heat recovery

- Application: dry machining operations, fine dust

- Filter installed outside the building

Solutions

HF designed and installed a complete ATEX-certified filtration system specifically engineered to manage dust generated by dry machining operations. The system integrates explosion protection solutions and is configured with filtered air recirculation, enabling heat recovery.

Advantages

- High level of operational safety (ATEX)

- Effective control of fine dust

- Protection against explosion risks

- Improved air quality

- Stable environmental conditions

- Optimized energy efficiency